Simulations

that work for you

Simulations

Batenburg has extensive expertise in simulation solutions, both in mechanical engineering and process control.

We use simulations to work even more efficiently, increase the quality of the software and reduce risks in complex processes.

For the design, validation and testing of machines and systems, Batenburg Techniek frequently uses simulations. Working with simulations is also a regular feature for purposes of training and communication.

Some simulation methods are simple, such as input/output (I/O) simulations. Others, on the other hand, are very complex. If this is the case, we use physical models to ensure maximum accuracy. Using a HoloLens application, we can simulate and test, without the physical machine being present. This saves a lot of time and reduces the chance of errors. It also allows us to make a virtual copy of the real, physical machine and link it to the real controller. In industry 4.0, this is called a ‘digital twin’. Such a twin allows you to first test changes virtually before implementing them on the machine. This way, the machine can be put into operation with software that has already been tested. A major advantage!

Would you like more information?

Kees van der Meijden

Sales Manager

Worth the investment

Batenburg Techniek supplies customised simulators and gets the most out of the investment.

We achieve this by using existing and already realised engineering data such as 3D drawings (mechanical) and models (MatLab, Orcaflex, Python). Or by upgrading the simulator for training purposes.

For a simulation, we often integrate separate components, such as PLC hardware, computers on which the models run, and visualisation software with VR goggles and a screen visualisation. The components together form a single simulator.

Machines are becoming increasingly complex and engineering lead times ever shorter. The means that there is less time for investigating and specifying everything beforehand. There is often a lack of ready knowledge because solutions are becoming increasingly innovative.

In the area of automation, Batenburg JB Systems has adapted its methods to this and developed tools that support this way of working.

SCRUM method

In order to implement complex projects in an efficient and effective way, Batenburg JB Systems decided a few years ago to adopt the SCRUM method within its procedures. Batenburg JB Systems has modified a number of aspects of the SCRUM method in order to make it workable within the area of industrial automation. Batenburg JB Systems has certified SCRUM masters to ensure that the method is implemented in the correct way.

Simulations

Simulation environments are important tools within the SCRUM methodology for being able to track and validate the developments of the software together with the client. There are various simulations:

- Functional simulations (I/O simulatie)

- 3D simulations

- Dynamic simulations

The advantages of simulation are:

- Insight into the automation solution at an early stage;

- Testing and validation take place independently of the real installation or machine, and

- Extensive testing without risk to the real installation or machine

Winmod

Batenburg JB Systems makes use of Winmod to realise the functional simulations. The company is also an official Solution Partner for Winmod.

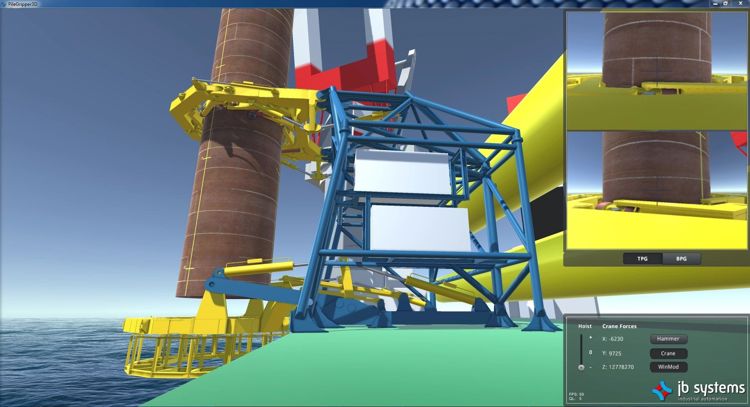

3D real time simulations

“A photo says more than a thousand words” (Arthur Brisbane 1911)

This saying is as valid today as ever. By making 3D visualisations on the basis of existing 3D files, such as FBX, DWG or STEP files, and linking these to the PLC control in real time, everyone involved in the project gets the same insights. 3D simulations are used for the following purposes:

- Testing

- Validation

- Ergonomics (spatial insight)

- Training purposes

- Commercial purposes

- Virtual Mockup

- Service purposes

- HIL testing

3D simulations can be supplied in various forms, during development of the software as a simple wire model for training purposes a realistic model, if necessary with dome or VR goggle.

Dynamic simulations

As the complexity of the applications increases, it is becoming increasingly important to consider dynamic behaviour in the development of the automation beforehand. JB Systems has extensive experience of the coupling of dynamic models to the functional and virtual simulations, e.g. on the basis of Matlab Simulink or Orcaflex.